Off-site manufacturing

Popular

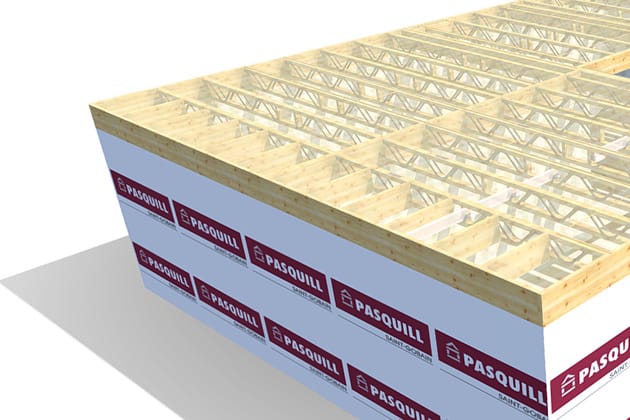

The use of cassette floor panels has become increasingly popular because they can improve safety on site and dramatically speed up the erection process.

Cassettes are manufactured using either JJI-Joists or Posi-Joists™ to meet customer requirements.

Safety straps

Lifting straps are built into the cassettes ensuring safe lifting for both transportation and site erection. The decking material is subject to the requirements of the final floor – OSB boarding, Plywood or Chipboard can all be specified.

Our design and factory teams work closely with customers’ technical and site personnel to ensure a smooth operation throughout the project.

Features & Benefits

- OSM floor solution

- Robust detail compliant / Part E (sound) compliant

- Reduced site construction time

- Controlled manufacturing environment ensures consistent quality

- Stability of an instant working platform

- Improved health & safety during construction process

- Easy installation of services, particularly Mechanical Ventilation & Heat Recovery systems

- Lifting straps attached for ease of transportation and installation

- Suitable for houses and low level apartments

- Eliminates need for highly skilled labour on site

- Firebreak characteristics can be incorporated into the design

- Constructed from timber and sustainable materials

- Chain of custody certified

- Ability to control and account for waste

- Cassettes can be sequentially loaded to speed up erection process

- Ideal for timber frame construction

FAQs

Floor cassettes are pre-fabricated flooring systems with structural components, insulation, and other essential elements. They accelerate construction by providing a complete and efficient solution for building floors.

In the context of construction, a cassette refers to a pre-fabricated unit incorporating structural components, insulation, and other essential elements for various building aspects. Cassettes simplify the assembly process, offering a convenient solution for roofs, floors, walls, and other structural components within a building.

A timber cassette system involves the use of prefabricated timber components in construction. It includes structural elements like beams and panels, promoting efficiency and precision in building projects.

A cassette panel is a prefabricated building component that combines structural elements, insulation, and cladding materials. It serves as a ready-made unit for walls, floors or roofs, providing efficiency and consistency in construction. Cassette panels are versatile and contribute to faster, more streamlined building processes.